Notes on The Economic Impact of Custom Boats.

With the launch of Anna — our new all-custom 65-foot daysiler, behind us, we’ve had a moment to consider not just the value of a new custom boat, but the value that custom boat creates.

Because if you think about it, a custom-boat’s value is subjective and straightforward: How much did she cost to build? How much might a new buyer pay for her? What might it cost for potential owners to have a similar experience with another yacht? No matter how unique a custom boat, her value is basically a few numbers agreed on by consenting adults.

But the value created by that all-custom boat — something like Anna that built by skilled craftspeople in a prosperous place like Maine, using the best possible global components — turns out to be a narrative as complex as custom vessels themselves.

What was the value in payroll and insurance to the workers who crafted that custom boat’s hull, interior and finishes? What impact did the design fees paid to her engineers and architects have to their local economies? How much did the cost of her hardware and systems flow to the workers and owners of those operations? The planks for custom boats doesn’t just come from Maine, these materials are shipped in from places like western North America and Southern Asia. Spars and rigging may be designed in New Zealand, but they are built in factories in Sri Lanka or South Africa. And machinery and propulsion systems might come from an Austrian propulsion company with a distributor in New Jersey.

It is a world of effort that goes in a 21st-century custom boat.

There are complex macroeconomic models that can quantify economic impact of custom projects like boats. These models are not content just to tally the series transactions of wages paid and materials purchased. They seek to shoot a valuation arrow through time, that not only captures what was paid in wages and materials, but the location of those payments and the time it took for those dollars to flow through rest of the various public and private sectors of the affected economies. Macro-impact models are fun to build, but they are complex, steeped in jargon and boring, to be honest, for many readers.

But we have found that exacting impact models are almost beside the point. Armed with nothing but well-known ratios for materials and labor, a pretty darn good model for the economic impact of a custom boat can be generated for the local and regional Maine economy, as well as a general sense for that boat’s effect nationally and globally.

And we are proud to say, a well crafted custom boat like Anna can have as attractive economics as the boat itself.

The Impact Of That Which is Built.

We’ve discussed elsewhere some ways of estimating build costs for custom and production boats: (LINK TO EARLIER STORIES), and how those costs will cover a range, depending on factors like weight, complexity and degree of finish. Let’s talk through some basic assumptions for a “middle of the road” custom boat in the 75-foot range. For a custom boat of this size, there are two simple ratios that establish value:

- 40 cents out of every dollar spent on a boat, goes to paying the labor.

- 60 cents out of every dollar goes to the materials and systems.

So, for our 75-foot custom concept boat, of around 90,000 lbs or 45 tons, will have labor costs that breaks down like this.

- 40 people will share something like $3 million to design, engineer and build that marvelous boat

Then using our handy 60/40 rule, depending on specification and complexity, inputs for this boat feel like this:

- Materials and systems should round off to about $4.5 million.

That all implies for our 75 ft concept example, labor, fees, materials and systems lead us to a total cost of construction that feels like this:

- Payroll, fees and materials total approximately $7.5 million.

The Impact of What Gets Spent.

Now we have a basic cost of our 75-footer. But what about the impact of all those wages and materials? What amount of that money in payroll, or cost of materials like wood, stainless steel, and carbon fiber — additionally, the mechanical and electronics costs — are in turn spent on housing, goods, food and maybe a night on the town? How do we get a feeling for the multiplicative impact of those dollars that flowed through a custom boat of this size?

To calculate the additional value created by major projects like boats, economists have developed clever tools called input multipliers. These multipliers are based on known ratios that simplify the amplification effect of various kinds of investments and spending into easy-to-deal-with small numbers.

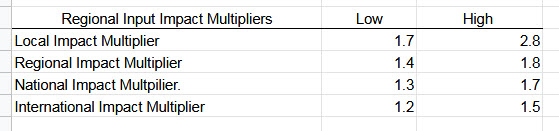

We surveyed various multipliers that relate to the marine industry from the U.S. Bureau of Economic Analysis, the State of Maine IMPLAN impact models and similar methodologies used in the commercial waterfront models both in Maine and the State of California.

We laid out the relevant multipliers in the marine industry, to the right.

See what these figure say? At the very least, every single dollar spent on a boat creates another $.20 in impact value. But in more regional areas, more deeply affected by high paying jobs like custom boat building, impact multipliers can creep to nearly 2.8 times those dollars spent.

The range of our impact stories for our concept 75-footer looks like this:

- $7.5 million total cost x 1.2 Impact Factor = $9.0 million

- $7.5 million total cost x 2.8 Impact Factor = $21.0 million

As startling as those ranges of value are to consider, are they really all that outrageous? Craftsmen can earn lucrative wages of up to $35 an hour! That kind of salary allows for discretionary spending in housing, education and investment that changes lives and communities. It’s why Henry Ford tripled Ford’s factory workers wages a hundred years ago to create the U.S middle class. And why industrializing economies like China were careful to build walls around its domestic industry.

Even the chance to keep industrial spending near at hand, creates wealth at unimaginable scale. That why we get so excited about considering the impact of custom boats like Anna. What would the economic impact be of a hundred Anna’s being built in Maine? That kind of construction goes on in places like Holland or Hong Kong.

That would be a perfect storm of value and prosperity.