Amped on Electric Boats

14 years ago we launched an innovative custom design– the hybrid diesel/electric-runabout, Zogo. The 29-footer built by French & Webb, features a solar canopy and is equipped with a seven-kilowatt generator/motor integrated onto a 110-horsepower diesel engine from Steyr Diesel of Austria. At full throttle under the 110 hp diesel, the hull reaches 17 kts. Cutting-edge for the time, in the decade-plus that has transpired, systems technology for electric boat design has progressed significantly. As Stephens Waring embarks on a more contemporary electric boat project, (introducing Isobel), we’re sharing some of the exciting developments we’re integrating into our current designs and we’ll highlight new technologies we see just around the corner.

Why Electric?

There are plenty of legit reasons to embrace electric boat concepts. First and foremost, electric boats have zero direct emissions, contributing to cleaner waterways and reduced environmental impact. They also have fewer moving parts. Compare the nearly 2,000 moving parts on an internal combustion drivetrain to the 20 moving parts on an electric-based system. The result is a reduction in maintenance and an improvement in overall reliability.

Electric boats do away with engine oil, gasoline, exhaust fumes and coolant fluids, making them cleaner to operate and easier to maintain.

And when the juice is flowing the ride is serene. Electrics are quiet; with a near silent operation like the new cars on the market, they reduce noise and vibration providing a tranquil ride through the water that is a welcome boating experience for anyone.

However, an apples-to-apples replacement of a big ICE motor with an electric system is not quite market-ready on a commercial scale. Today’s iteration of batteries and powertrains, (while improving all the time) are heavy, which limits a boat’s performance and range. The variety of suppliers and availability of battery systems pose challenges with high raw material prices and slow delivery times.

However, the potential for a near-infinite range using solar and regenerative power sources provides an alluring opportunity to explore waters far from any fuel station. Furthermore, Electric boats enjoy access to certain waterways off limits to ICE vessels across Europe, including some of the most pristine and beautiful lakes of the Alps, as well as hundreds of lakes and reservoirs in the US.

And while there is an environmental cost incurred from the mining and production of rare earth metals needed to construct batteries, many battery manufacturers advertise the ecological benefit of electrics can be realized in as little as six months of operation.

Rethinking the Whole Design

One of the biggest challenges with respect to electrics is how to deal with the weight of batteries. The challenge is a basic physics equation. Weight equates to resistance. The distance and speed you will be able to travel in your electric boat comes down to how much energy and power it takes to move the weight of your boat against the resistance and force of the water.

One solution is to take a holistic top-down approach to design. The entire vessel needs to be built around efficiency, not just the electric propulsion system. This involves reducing drag and resistance, sometimes through innovations like hydrofoils or in the design of hulls capable of planing at lower speeds. Earlier attempts at electric boat design took traditional exoskeleton and hull designs and simply transplanted batteries and electric motors where fuel and ICEs were before. The result is a more expensive boat with less performance. However, by starting with new and innovative thinking the puzzle is becoming solved.

Sweden-based Candela has partnered with Polestar (part of Volvo) to create several unique hydrofoil designs which target both the recreational and commercial markets. Their test-drive-ready C-8 is powered by a 69 kWh battery pack that runs an efficient DC system. Once the 28-foot boat reaches a speed of 16 knots (18 mph), two retractable foils lift its hull out of the water, greatly reducing hydrodynamic friction. As a result, one charge of the C-8’s battery pack is good for a range of 50 nautical miles at a speed of 20 knots. A digital control system automatically adjusts the carbon fiber foils to keep the boat level and steady, even in adverse weather conditions. The foils and propulsion unit are retractable for trailing, storage, and shallow water operation.

Another electric boat manufacturer embracing the hydrofoil revolution is Navier. Their latest design, the Navier 30 combines state of the art aerospace flight control and cutting edge hydrofoiling technology to build a boat 10x more efficient than traditional 30-ft class boats while providing a range of 75 nautical miles at 20 knots. Navier co-founders Sampriti Bhattacharyya and Reo Baird signed with Lyman-Morse Boatbuilding in Thomaston, Maine to build the pre-production vessels and first year limited production vessels.

The Lithium Game Changer:

For decades the only viable battery technology was lead-acid where the limitations prevented much innovation. Lithium-based battery architecture has advantages over traditional lead-acid batteries and, along with road vehicles, has caused a resurgence in interest in electrifying boats.

Lithium batteries are smaller and lighter while packing a greater range of energy transfer. This smaller lighter size is especially beneficial in a boat because weight can directly affect buoyancy, speed, and maneuverability. Lithium batteries will run four times longer than a lead-acid battery with the same weight. In a direct comparison between a lead-acid battery and a lithium battery with equal volts and amps, the lithium battery is nearly 20% more efficient.

Lithium batteries are smaller and lighter while packing a greater range of energy transfer. This smaller lighter size is especially beneficial in a boat because weight can directly affect buoyancy, speed, and maneuverability. Lithium batteries will run four times longer than a lead-acid battery with the same weight. In a direct comparison between a lead-acid battery and a lithium battery with equal volts and amps, the lithium battery is nearly 20% more efficient.

The amount of lithium power being banked on electric boats is impressive. US-based Arc Boats is developing a first model waterski boat which will host a 200 kWh 800-volt battery pack with at least 475 horsepower and a speed of 40 mph. The boat is able to easily plane and pack plenty of punch through waves and sure to offer a thrilling ride for anyone in tow.

Another Lithium technology gaining traction is Lithium Iron Phosphate (LFP) batteries. LFP battery technology is a type of Lithium ion battery that uses iron phosphate as the cathode material. In turn, the cathodes produce a relatively high energy density which creates a longer running life and better performance, even at higher temperatures. The tradeoff comes with lower cost for slightly-heavier-than Lithium Nickel Manganese Cobalt Oxide (NMC) batteries found commonly in electric cars. Additionally due to lower cost, high safety, low toxicity, long cycle life and other factors, LFP batteries are finding a number of roles where economics and safety are the priority. LFPs may not be the best battery choice for a high speed high power electric boat, but they are becoming increasingly popular with sailboat owners, where the increased battery weight in relation to the size of the boat is less important and speed under power is a smaller downside issue.

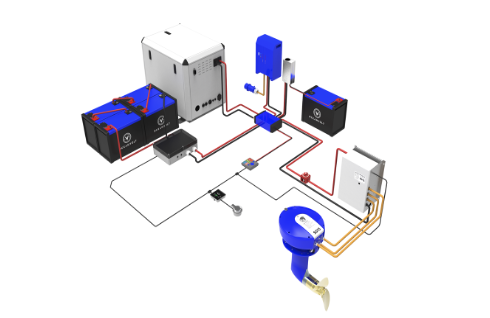

Bridging the Electric Gap

An exciting interim step towards reaching a lower carbon footprint and embracing electric technology is the diesel-hybrid system; this is the system we employed on ZOGO in 2009. Italian company e-Motion has created a parallel hybrid system that offers a range of solutions including traditional engines, mixed diesel/electric, or electric only. Their system consists of diesel engines, variable speed generators with internal inverters, permanent magnet alternators to increase the electric efficiency, a lithium battery pack, control panel, and the panel for onboard utilities. Everything is regulated by the software. In practice, the software customizes the system to adapt to the type of performance and mode of operation wanted by the skipper.

These modes include diesel/electric cruising with engines off and generators on; zero-emissions cruising with electric propulsion only; “economy” cruising with one diesel engine for propulsion and electricity plus an electric motor for the second shaft; “power boost” mode with both engines and generators for greater thrust. What’s so fun? Zero emissions at anchor: the electrical utilities are fuelled purely by the batteries or “fast charge” with the variable speed generators and the electric motors coupled with the propulsion engines in neutral. The end result can be a 30% savings in fuel consumption compared with traditional systems.

Another hybrid system growing in popularity for sailboats is Hydro generation or sail regeneration. This allows sailboats to generate power undersail by using the prop to generate power from the boat’s movement through the water to recharge its batteries. The tradeoff is just a small penalty in sailing speed. This regenerative system is particularly useful in vessels that sail at a high speed, like catamarans or larger monohulls, as the power produced goes up exponentially with velocity, while the drag stays lower.

More sophisticated systems such as the OceanVolt Servo Prop 25 include a variable pitch propeller which can fine-tune the angle of the prop blades to optimize energy generation based on wind conditions. And with the blades set to the neutral sailing position, the prop can have extremely low drag similar to a regular feathering prop. The Oceanvolt ServoProp 25 can generate 5kW of power at 10 kts under sail. When flipped into output mode it produces a nominal power of 25 kW, with peak power of 30kW for periods up to 15 minutes. The equivalent of 75 horsepower.

Finding a Charge

Finding a Charge

Finally, a new development that is making electric boat life easier today is the introduction of super-charging stations at marinas. Aqua superPower is a fully marine-specific dockside network of fast chargers for electric boats. Aqua’s network has connected software and an accessible app connecting boat owners to 150 kW fast chargers, specifically engineered and rated for use in marine environments. The company has over 150 stations in Europe including Cote d’Azur, the Italian Riviera, Venice, Spain, Portugal, the UK, Sweden, and Canada, and recently, they installed their first US location in Lake Tahoe.

Embracing the Electric Future

With so many twists and takes on electric boat design, it’s clear a true winner for the perfect electric boat design has yet to be crowned. The reality is that for the foreseeable future boat owners and designers will need to experiment with different design packages that address specific needs of the end user. Fortunately, this is a big part of the fun. It’s also where Stephens Waring can help with understanding client’s needs and can identify the appropriate solution.

Like any emerging technology it is often the consumer and their set of priorities and preferences that will steer the ultimate course of technological development. Necessity drives innovation, and for us at Stephens Waring, our clients play an important role as partners at the design table. Whether it’s the need for speed, range, comfort, or cost (and likely a combination of all), Stephens Waring is excited to learn from and work with our peer set, the growing number of innovative suppliers, and our clients to bring new ideas to life.

Related Articles:

https://stephenswaring.com/electric-commuter/

https://stephenswaring.com/what-is-the-cost-to-own-an-all-electric-boat-anyway/

https://stephenswaring.com/marine-engineering-104-what-keeps-whats-inside-my-boat-inside-my-boat/