The Complicated Life of the Modern Transom

Given the variety in styling, operational performance, and construction made possible by current design aesthetics and materials, the modern transom is often one of the more detailed elements of a yacht’s design. On Cirrus, the 68-foot, Spirit of Tradition sailing sloop in-build at James Betts Enterprises (click here for build photos) in Anacortes, Washington, we went for a fairly traditional looking transom to match her sweetly shaped haunches. In Cirrus’s case, however, looks most certainly are deceiving.

With the push of a button, or operations made manually, convertible transom designs are found on all manner of yachts. A transom with opening geometry may hinge down, retract into concealed slots, or swing open. What is true with all these arrangements is that they’re intended to give better access nearer to the waterline resulting in increased functionality. Once the transom becomes convertible it creates user-friendly access—easy swimming or boarding from the dinghy or dock is made simpler and safer. Additionally with this transom-supported access, if designed as a door when the platform opens we now have the “garage”, the area of the hull under the aft deck or cockpit for storage of boat essentials including safe protected stowage for dinghies. It’s no wonder so many convertible ideas for transoms are design choices on many different yachts—sail or power.

Cirrus is a solid sailing yacht designed to provide her owners with luxury comforts while cruising long distance passages and near-shore explorations. With long sweeping sheer, a lovely trailing counter, and deck styling inspired from 40’s and 50’s era yachts, her design is aimed squarely along the continuum of a rapidly swelling Spirit of Tradition genre. To read more about how SoT is defined and considered, review our writings here and here. Aboard this beautiful boat, fully loaded with carbon fiber and foam core sandwiches and the most current technical refreshments we can add for her tasty interior comforts, we highlight the detailed work designed into her aft lazarette and transom garage because hidden beneath, these things potentially go unseen to the public eye. Concealed within, a deeper look shows how important is the forethought her owner gives to the usage of his craft.

Cirrus is a solid sailing yacht designed to provide her owners with luxury comforts while cruising long distance passages and near-shore explorations. With long sweeping sheer, a lovely trailing counter, and deck styling inspired from 40’s and 50’s era yachts, her design is aimed squarely along the continuum of a rapidly swelling Spirit of Tradition genre. To read more about how SoT is defined and considered, review our writings here and here. Aboard this beautiful boat, fully loaded with carbon fiber and foam core sandwiches and the most current technical refreshments we can add for her tasty interior comforts, we highlight the detailed work designed into her aft lazarette and transom garage because hidden beneath, these things potentially go unseen to the public eye. Concealed within, a deeper look shows how important is the forethought her owner gives to the usage of his craft.

Transom Transformation

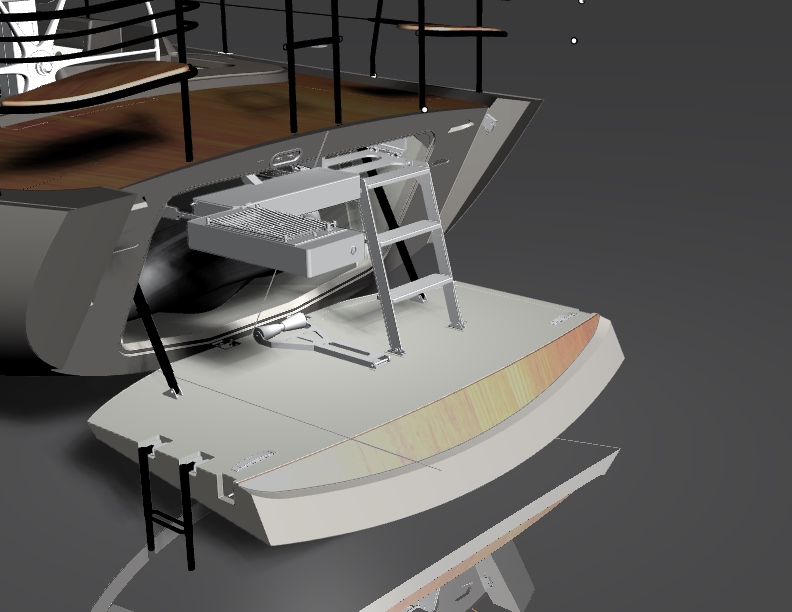

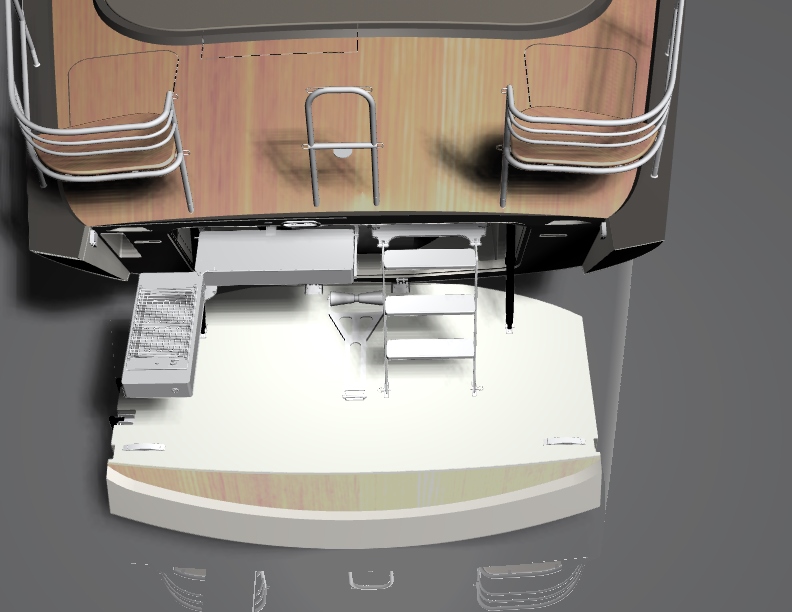

Aboard Cirrus, the push of a button causes electric actuators to lower the transom surface–transforming her stern from standing as the elegant endpoint of her hull’s beauty to practical utility: a 3 ft x 9 ft. platform and storage garage combination. To access the platform from the stern deck, a carbon-fiber ladder on its Harken slide system deploys into place automatically as the platform lowers. On the platform are pop-up cleats for tying off the tender, and a telescoping swim/rescue ladder that stows within a recess inside the platform structure.

In cases of catastrophic emergency, or a person-overboard, the platform can be deployed by a person in the water via the emergency button located in the hull’s counter. For offshore safety, the door is made watertight when the electric actuators force the door closed against a hollow rubber gasket around the perimeter of the garage opening.

Over-the-top?

While making boarding issues so darned accessible, Cirrus’s owner will enjoy his time aboard when his aft platform turns outdoor kitchen. A slick Italian made Techimplex electric grill is cleverly arranged on a complicated drawer system for easy stowage and saving of space. Releasing a cable-driven lever catch allows the drawers to drop from their stowed position under deck, and out slides the grill and carbon composite counter. The grill and counter travel on two heavy-duty drawer-slides and when fully deployed, the counter secures in place with the grill fabrication hinged outboard to port. When cooking is done, the cable driven latching system releases the grill and the counter system to slide back under the deck where gas-assist springs push the fabrication upward for stowing out of the way of the tender.

The Tender

Lowering the transom platform exposes Cirrus’s garage which contains the Achilles 3.2-meter hard-bottom inflatable. The tender is chocked stern-forward, engine stored safely on the floor, with its pontoons fitting each side of the carbon-fiber rudder post and under the wheel well created to recess the six-foot diameter carbon-fiber wheel. To load, simply unpin the carbon-fiber ladder and slide it out of the way under the deck. Next flip over the transom-edge roller which gives you and an accomplice the ability to simply pick up the stern of the dinghy, put the centerline on the roller, then pull the dinghy up and into the garage with help of another roller at the garage entrance. Clean and simple. A transom garage creates a nice, snug position sheltered from weather for any length passage.

Where the Rubber Meets the…err, Transom

Although providing simple daily operations and great looks, Cirrus’s transom door is a pretty complicated piece of design. The platform is able to handle a lot of various loading—twisting or racking from crew weight and the dinghy rolling aboard. Then there’s seaworthiness, a job all transoms must provide. The structure is stiff enough to evenly and consistently compress a gasket. Finally, the hinge geometry must be robust and laid out so the platform lands at a good workable distance off the water, with enough width for hosting multiple functions, and blend seamlessly into her hull.

Completely Hinged

Hull shape in Cirrus’s transom and hinging geometry dictated that the transom platform be a relatively thick, wedge-shaped section. To construct this piece, builder Jim Betts CNC-cut three molds: one for the fixed structural areas tying the boat together across the stern; another to create the outside cambered surface, perimeter door edges, and the sweeping raised bulwark; then, a third mold providing the shape of the inside, or working platform surface. The structure is stiffened with longitudinal and transverse vertical stiffeners that provide support for the fittings mounting the electrical actuators, and strong enough to carry loads across the platform. Like the entire yacht, the structure is all carbon-fiber laminates. This engineering and construction has created a transom door that is clean in appearance and dramatically useful for our client.

Transom configurations have evolved dramatically since the early days of ship and yacht design. Given that safety and practicality are priorities, the result of concentrated planning provides easy accessibility and efficient storage organization. An opening transom isn’t everyone’s dream, but what’s not to love?